|

In this issue: Featured video: Transcatheter Heart Valve To view newsletter in your browser click here. Mechatronics Sense readers: |

|

| See the Transcatheter Heart Valve video |

|

The Edwards Sapien 3 Transcatheter Heart Valve as the name indicates, is implanted through a catheter instead of opening up a patients chest. Edwards has clinical trials showing 75% reduction in mortality and disabling stroke risk compared to surgery. |

|

| The channel that blood flows through inside an artery is referred to in medicine as lumen. So, how small an area are surgeons working with? The lumen diameter in one study of 70 people and measured at 96 points, was 4.5 mm ±0.5 mm for the left main artery and the proximal left anterior descending coronary artery (LAD) was 3.7 +/- 0.4 mm.3 When expanded by the balloon, the valves could be 20 mm or larger.1 The simulation video shows this amazing process. See the video: https://www.youtube.com/watch?time_continue=13&v=LVgf9bbGxYY |

|

| Sources: 1) https://www.edwards.com/devices/heart-valves/transcatheter-Sapien-3 2) https://www.asme.org/engineering-topics/articles/bioengineering/top-5-medical-technology-innovations 3) http://circ.ahajournals.org/content/86/1/232 |

|

| What is IO-Link?

It enables sensors, actuators and other devices to connect to a network and provides fieldbus functionality but is point-to-point communication, so it not classified as a fieldbus. Communication to a master device is bi-directional and the IO-Link master can transmit this data over various networks, fieldbuses or backplane buses, making the data accessible for PLCs and HMI.

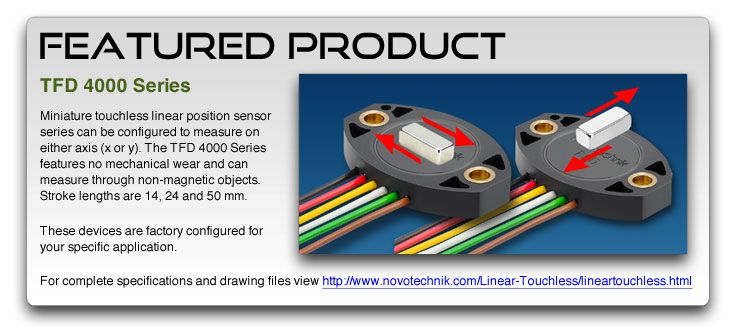

IO-link technology increases productivity and uptime because it includes diagnostic information that reports whether a sensor is functioning or in need of replacement. This means users don’t have to check every sensor in a system if a problem occurs. By using simple 3-wire connectivity that does not have to go all the way to a PLC from a sensor, IO-Link devices are easier to set up and maintain. IO-Link can handle thousands of devices from more than 150 manufacturers on one cable. The bi-directional data also permits adjusting the sensor from the controller. The protocol allows for cyclic and acyclic service-data communication, separately from process data communication. These features greatly increase flexibility and scalability. Because IO-Link sensors can function like traditional 3-wire sensors when not connected to IO-Link systems, the same part can be stocked for other applications, lowering inventory costs. Several of the features described in the preceding paragraphs can lower operating costs as well. One really nice feature IO-Link provides is that by using a unique identifier for each device, it can store each sensor’s configuration values in an IO-Link master. This means that if a sensor needs to be replaced, when the new one is plugged in, it is automatically programmed to the stored setting values and ready to go. Among the sensors Novotechnik offers, one excellent example of an IO-Link device is the RFC 4800. View the manual and specifications for the RFC 4800 here.

|

|

If you have a question about position sensors for your specific application, Novotechnik engineers would be glad to speak with you. Contact us at Email Novotechnik info@novotechnik.com or call 800-667-7492. Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor editor@novotechnik.com |